Fault-tolerant control of a double star induction machine operating in active redundancy

DOI:

https://doi.org/10.20998/2074-272X.2025.6.04Keywords:

double star induction machine, active redundancy, field-oriented control, reliabilityAbstract

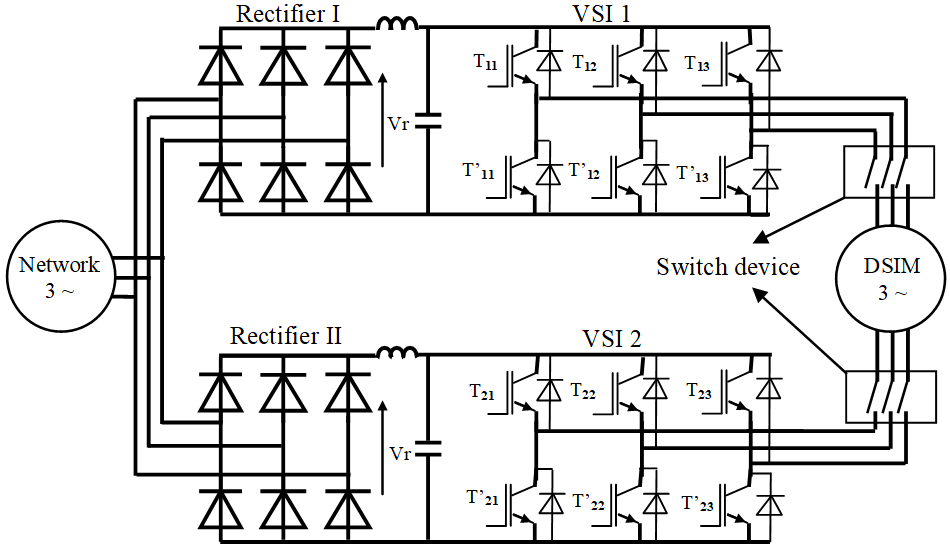

Introduction. The operating safety of a variable-speed drive is of paramount importance in industrial sectors, such as electric propulsion for ships, rail transport, electric cars, and aircraft, where reliability, maintainability, and safety are top priorities. Problem. One solution to improve the availability of a variable-speed drive is the use of a double star induction machine (DSIM). This machine can provide active or passive redundancy. Redundancy is active if both converters operate simultaneously, and the failure of one of them does not affect system operation. Passive redundancy is passive if only one converter is operating and the 2nd is on standby; the latter will only operate if the first fails. Goal. Improving the availability of a DSIM by the operation in active redundant of the machine supply system. Methodology. Use scalar control to control the machine power system in active redundancy. Simulation results with this scalar control demonstrated the need to equip this control with a decoupling of the variables responsible for machine magnetization and torque production. Field-oriented control (FOC) is then used to ensure the reconnection of a converter after a failure for active redundancy operation, without the risk of significant torque ripples. Scientific novelty. To increase the availability of the variable speed drive, an original control strategy for reintegrating the repaired faulty inverter is implemented to allow the repaired inverter to resume operation of the drive motor. This strategy control is based on the specific use of FOC to resynchronize the output frequency of the repaired inverter with the motor speed. Results. The results demonstrated the value of vector control in each star power supply system to avoid transient over currents at the input of the 2nd converter, by synchronizing the frequency of the 2 converters to the rotor speed. Practical value. An experimental model around a DSIM is set up to validate the active redundancy operation of the system. Active redundancy provides the variable speed drive with an increase in the reliability of the variable speed drive and significantly improves the availability rate of the driven load, since the disconnection of one of the 2 converters following a failure does not affect the operation of the machine. References 17, tables 2, figures 13.

References

Nemouchi B., Rezgui S.E., Benalla H., Nebti K. Fractional-based iterative learning-optimal model predictive control of speed induction motor regulation for electric vehicles application. Electrical Engineering & Electromechanics, 2024, no. 5, pp. 14-19. doi: https://doi.org/10.20998/2074-272X.2024.5.02.

Chaib Ras A., Bouzerara R., Bouzeria H. An adaptive controller for power quality control in high speed railway with electric locomotives with asynchronous traction motors. Electrical Engineering & Electromechanics, 2024, no. 2, pp. 23-30. doi: https://doi.org/10.20998/2074-272X.2024.2.04.

Khemis A., Boutabba T., Drid S. Model reference adaptive system speed estimator based on type-1 and type-2 fuzzy logic sensorless control of electrical vehicle with electrical differential. Electrical Engineering & Electromechanics, 2023, no. 4, pp. 19-25. doi: https://doi.org/10.20998/2074-272X.2023.4.03.

Guizani S., Nayli A., Ben Ammar F. Comparison between star winding and open-end winding induction machines. Electrical Engineering, 2016, vol. 98, no. 3, pp. 219-232. doi: https://doi.org/10.1007/s00202-016-0359-4.

Sun J., Zheng Z., Li C., Wang K., Li Y. Optimal Fault-Tolerant Control of Multiphase Drives Under Open-Phase/Open-Switch Faults Based on DC Current Injection. IEEE Transactions on Power Electronics, 2022, vol. 37, no. 5, pp. 5928-5936. doi: https://doi.org/10.1109/TPEL.2021.3135280.

Letellier Р. Electrical propulsion motors. Electric Propulsion. Тhе Effective Solution. Paper 7. London, IMarE, 1995.

Mitcham A.J., Cullen J.J.A. Motors and drives for surface ship propulsion: comparison of technologies. Proceeding of 1995 Electric Propulsion Conference, 1995, vol. 4, pp. 88-89.

Abdel-Khalik A.S., Masoud M.I., Williams B.W. Vector controlled multiphase induction machine: Harmonic injection using optimized constant gains. Electric Power Systems Research, 2012, vol. 89, pp. 116-128. doi: https://doi.org/10.1016/j.epsr.2012.03.001.

Abdelwanis M.I., Zaky A.A. Maximum power point tracking in a perovskite solar pumping system with a six-phase induction motor. Revue Roumaine des Sciences Techniques – Série Électrotechnique et Énergétique, 2024, vol. 69, no. 1, pp. 15-20. doi: https://doi.org/10.59277/RRST-EE.2024.1.3.

Lim C.S., Lee S.S., Levi E. Continuous-Control-Set Model Predictive Current Control of Asymmetrical Six- Phase Drives Considering System Nonidealities. IEEE Transactions on Industrial Electronics, 2023, vol. 70, no. 8, pp. 7615-7626. doi: https://doi.org/10.1109/TIE.2022.3206703.

Hammad R., Dabour S.M., Rashad E.M. Asymmetrical six-phase induction motor drives based on Z-source inverters: Modulation, design, fault detection and tolerance. Alexandria Engineering Journal, 2022, vol. 61, no. 12, pp. 10055-10070. doi: https://doi.org/10.1016/j.aej.2022.02.058.

Boukhalfa G., Belkacem S., Chikhi A., Benaggoune S. Genetic algorithm and particle swarm optimization tuned fuzzy PID controller on direct torque control of dual star induction motor. Journal of Central South University, 2019, vol. 26, no. 7, pp. 1886-1896. doi: https://doi.org/10.1007/s11771-019-4142-3.

Chaabane H., Khodja D.E., Chakroune S., Hadji D. Model reference adaptive backstepping control of double star induction machine with extended Kalman sensorless control. Electrical Engineering & Electromechanics, 2022, no. 4, pp. 3-11. doi: https://doi.org/10.20998/2074-272X.2022.4.01.

Zemmit A., Messalti S., Herizi A. New Direct Torque Control of Dual Star Induction Motor using Grey Wolf Optimization Technique. Przegląd Elektrotechniczny, 2024, no. 2, pp. 109-113. doi: https://doi.org/10.15199/48.2024.02.21.

Abdelwanis M.I., Zaky A.A., Selim F. Direct torque control for a six phase induction motor using a fuzzy based and sliding mode controller. Scientific Reports, 2025, vol. 15, no. 1, art. no. 14874. doi: https://doi.org/10.1038/s41598-025-97479-1.

Moussaoui L. Performance enhancement of direct torque control induction motor drive using space vector modulation strategy. Electrical Engineering & Electromechanics, 2022, no. 1, pp. 29-37. doi: https://doi.org/10.20998/2074-272X.2022.1.04.

Aib A., Khodja D.E., Chakroune S., Rahali H. Fuzzy current analysis-based fault diagnostic of induction motor using hardware co-simulation with field programmable gate array. Electrical Engineering & Electromechanics, 2023, no. 6, pp. 3-9. doi: https://doi.org/10.20998/2074-272X.2023.6.01.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 S. Guizani, A. Nayli, F. Ben Ammar

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Authors who publish with this journal agree to the following terms:

1. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.