The effect of thermal ageing on electrical and mechanical properties of thermoplastic nanocomposite insulation of power high-voltage cables

DOI:

https://doi.org/10.20998/2074-272X.2024.3.09Keywords:

low density polyethylene, nano filler, micro filler, dielectric strength, thermal ageing, thermogravimetric analysisAbstract

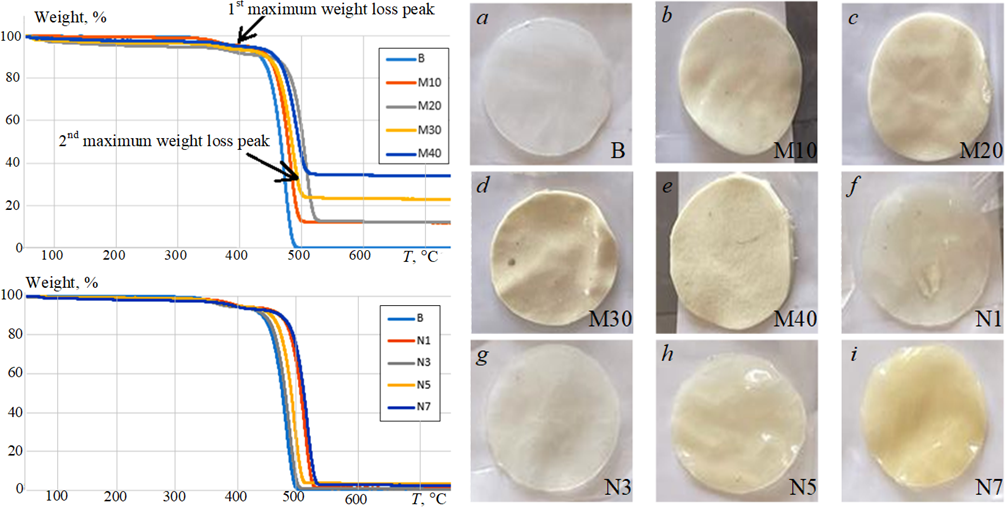

This research explores the thermal ageing influence on the Low Density Polyethylene (LDPE) dielectric properties, which is utilised as electrical insulation in high-voltage cables. An accelerated thermal ageing test was done at four temperature ranges ranging from 25 °C to 120 °C to define the degree of material deterioration under thermal ageing and to prevent its failure. LDPE composite samples were made by adding aluminium oxide (Al2O3) inorganic filler in two different grain sizes (nano and micro) with various concentrations. The effect of adding inorganic filler on the acceleration of the thermal ageing of the polymer was studied by heating the samples for different periods of time and measuring the dielectric strength of the samples. The obtained results show that thermal ageing considerably affects the electrical properties of the material. The LDPE/Al2O3 nanofiller sample has the highest dielectric strength value at different temperatures. Thermogravimetric analysis was used to investigate the thermal characteristics of materials. The mechanical characteristics of LDPE polymer are studied using tensile strength and elongation at break tests. References 27, table 4, figures 6.

References

Shimada A., Sugimoto M., Kudoh H., Tamura K., Seguchi T. Degradation distribution in insulation materials of cables by accelerated thermal and radiation ageing. IEEE Transactions on Dielectrics and Electrical Insulation, 2013, vol. 20, no. 6, pp. 2107-2116. doi: https://doi.org/10.1109/TDEI.2013.6678859.

Wang Y., Wang C., Zhang Z., Xiao K. Anti-thermal aging properties of low-density polyethylene-based nanocomposites. IEEE Transactions on Dielectrics and Electrical Insulation, 2018, vol. 25, no. 3, pp. 1003-1013. doi: https://doi.org/10.1109/TDEI.2018.006783.

Huang X., Xie L., Yang K., Wu C., Jiang P., Li S., Wu S., Tatsumi K., Tanaka T. Role of interface in highly filled epoxy/BaTiO 3 nanocomposites. Part II- effect of nanoparticle surface chemistry on processing, thermal expansion, energy storage and breakdown strength of the nanocomposites. IEEE Transactions on Dielectrics and Electrical Insulation, 2014, vol. 21, no. 2, pp. 480-487. doi: https://doi.org/10.1109/TDEI.2013.004166.

Wang C., Wang J., Wu C., Li W., Yang Z., Wu K. Study on Thermal Conductivity of BNNs/Mg(OH) 2 /LDPE Composites Based on Melt Blending Method. 2021 IEEE International Conference on the Properties and Applications of Dielectric Materials (ICPADM), 2021, pp. 214-217. doi: https://doi.org/10.1109/ICPADM49635.2021.9493996.

Kong X., Du B., Li J., Zhang Z., Xiao M., Zhu W., Su J., Jiang T., Liang H., Yang D., Pan X. Effects of high thermal conductivity LDPE/BN composites on temperature field distribution and ampacity of power cable. 2018 12th International Conference on the Properties and Applications of Dielectric Materials (ICPADM), 2018, pp. 45-48. doi: https://doi.org/10.1109/ICPADM.2018.8401025 .

Wang X., Lv Z., Wu K., Chen X., Tu D., Dissado L.A. Study of the factors that suppress space charge accumulation in LDPE nanocomposites. IEEE Transactions on Dielectrics and Electrical Insulation, 2014, vol. 21, no. 4, pp. 1670-1679. doi: https://doi.org/10.1109/TDEI.2014.004292.

Zhang C., Ren Z., Ren Q., Zhao H. Influence of nanoparticle morphology on the direct current dielectric properties of polypyrrole/LDPE nanocomposites. Fuhe Cailiao Xuebao/Acta Materiae Compositae Sinica, 2023, vol. 40, no. 5, pp. 2598-2608. doi: https://doi.org/10.13801/j.cnki.fhclxb.20220809.009.

Maur S., Chakraborty B., Dalai S., Chatterjee B. Investigation on Effects of Thermal Ageing on LDPE Based on Polari zation and Depolarization Currents. 2020 IEEE 1st International Conference for Convergence in Engineering (ICCE), 2020, pp. 200-204. doi: https://doi.org/10.1109/ICCE50343.2020.9290689.

Guo C., Li J., Gao Y., Liu B., Du B. Effect of Nanoparticle Type on Charge Transport Characteristics of LDPE/Micro-BN composite with High Thermal Conductivity. 2023 IEEE 4th International Conference on Electrical Materials and Power Equipment (ICEMPE), 2023, pp. 1-4. doi: https://doi.org/10.1109/ICEMPE57831.2023.10139611.

Kong X., Du B., Li J., Xiao M., Mu J. Effects of high thermal conductivity on power cable ampacity with LDPE/BN composites. 2017 IEEE Conference on Electrical Insulation and Dielectric Phenomenon (CEIDP), 2017, pp. 505-508. doi: https://doi.org/10.1109/CEIDP.2017.8257649.

Wang Y., Wang C., Zhang Z., Xiao K. Anti-thermal aging ability of low density polyethylene enhanced by MgO nanoparticles. 2017 IEEE Conference on Electrical Insulation and Dielectric Phenomenon (CEIDP), 2017, pp. 497-500. doi: https://doi.org/10.1109/CEIDP.2017.8257595.

Li Y., Wu J., Yin Y. Study on Conductivity Characteristics of LDPE/SiO2 Nanocomposite at High Temperature. 2023 IEEE 4th International Conference on Electrical Materials and Power Equipment (ICEMPE), 2023, pp. 1-4. doi: https://doi.org/10.1109/ICEMPE57831.2023.10139744.

Wang Y., Wang C., Zhang Z., Xiao K. Effect of Nanoparticles on the Morphology, Thermal, and Electrical Properties of Low-Density Polyethylene after Thermal Aging. Nanomaterials, 2017, vol. 7, no. 10, art. no. 320. doi: https://doi.org/10.3390/nano7100320.

Li Z., Liu N., Gabriel S., Chen G. Thermal ageing and its impact on charge trapping parameters in LDPE. 2017 IEEE Conference on Electrical Insulation and Dielectric Phenomenon (CEIDP), 2017, pp. 820-823. doi: https://doi.org/10.1109/CEIDP.2017.8257609.

Luyt A.S., Gasmi S.A., Malik S.S., Aljindi R.M., Ouederni M., Vouyiouka S.N., Porfyris A.D., Pfaendner R., Papaspyrides C.D. Artificial weathering and accelerated heat ageing studies on low-density polyethylene (LDPE) produced via autoclave and tubular process technologies. Express Polymer Letters, 2021, vol. 15, no. 2, pp. 121-136. doi: https://doi.org/10.3144/expresspolymlett.2021.12.

Wang Y., Wang C., Zhang Z., Xiao K. Anti-thermal aging properties of low-density polyethylene-based nanocomposites. IEEE Transactions on Dielectrics and Electrical Insulation, 2018, vol. 25, no. 3, pp. 1003-1013. doi: https://doi.org/10.1109/TDEI.2018.006783.

Hedir A., Slimani F., Moudoud M., Bellabas F., Loucif A. Impact of Thermal Constraint on the Low Density Polyethylene (LDPE) Properties. Lecture Notes in Electrical Engineering, 2020, vol. 599, pp. 952-960. doi: https://doi.org/10.1007/978-3-030-31680-8_92.

Suraci S.V., Fabiani D., Mazzocchetti L., Maceratesi V., Merighi S. Investigation on Thermal Degradation Phenomena on Low Density Polyethylene (LDPE) through Dielectric Spectroscopy. 2018 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), 2018, pp. 434-437. doi: https://doi.org/10.1109/CEIDP.2018.8544734.

Han B., Yin C., Chang J., Pang Y., Lv P., Song W., Wang X. Study on the Structure and Dielectric Properties of Zeolite/LDPE Nanocomposite under Thermal Aging. Polymers, 2020, vol. 12, no. 9, art. no. 2108. doi: https://doi.org/10.3390/polym12092108.

Wang Y., Li Y., Zhang Z. Space Charge Accumulation Characteristics of LDPE/TiO2 Nanocomposites under Thermal Aging. 2018 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), 2018, pp. 129-132. doi: https://doi.org/10.1109/CEIDP.2018.8544767.

ASTM D 3045: Standard Practice for Heat Ageing of Plastics Without Load. ASTM International, West Conshohocken, PA, 2020, 6 p.

ASTM E1131: Standard test method for compositional analysis by thermogravimetry. ASTM International, West Conshohocken, PA, 2020, 6 p.

Zheng Y., Tao L., Yang X., Huang Y., Liu C., Zheng Z. Study of the thermal behavior, kinetics, and product characterization of biomass and low-density polyethylene co-pyrolysis by thermogravimetric analysis and pyrolysis-GC/MS. Journal of Analytical and Applied Pyrolysis, 2018, vol. 133, pp. 185-197. doi: https://doi.org/10.1016/j.jaap.2018.04.001.

Jana R.N., Mukunda P.G., Nando G.B. Thermogravimetric analysis of compatibilized blends of low density polyethylene and poly(dimethyl siloxane) rubber. Polymer Degradation and Stability, 2003, vol. 80, no. 1, pp. 75-82. doi: https://doi.org/10.1016/S0141-3910(02)00385-3.

Pyra K., Tarach K.A., Janiszewska E., Majda D., Gora-Marek K. Evaluation of the Textural Parameters of Zeolite Beta in LDPE Catalytic Degradation: Thermogravimetric Analysis Coupled with FTIR Operando Studies. Molecules, 2020, vol. 25, no. 4, art. no. 926. doi: https://doi.org/10.3390/molecules25040926.

Marcilla A., Gomez-Siurana A., Odjo A.O., Navarro R., Berenguer D. Characterization of vacuum gas oil–low density polyethylene blends by thermogravimetric analysis. Polymer Degradation and Stability, 2008, vol. 93, no. 3, pp. 723-730. doi: https://doi.org/10.1016/j.polymdegradstab.2007.12.010.

ASTM D412: Standard test methods for vulcanized rubber and thermoplastic elastomers – tension. West Conshohocken, PA, 2016. 14 p.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 E. El Sherkawy, L. S. Nasrat, M. Rihan

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Authors who publish with this journal agree to the following terms:

1. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.