Requirements for cables as categories of construction products and thermal resistance of power cables

DOI:

https://doi.org/10.20998/2074-272X.2024.1.08Keywords:

urbanization, construction industry, cable infrastructure, fire safety, cable classification criteria, halogen-free compositions, power cables, thermal resistance, fire load, certified test baseAbstract

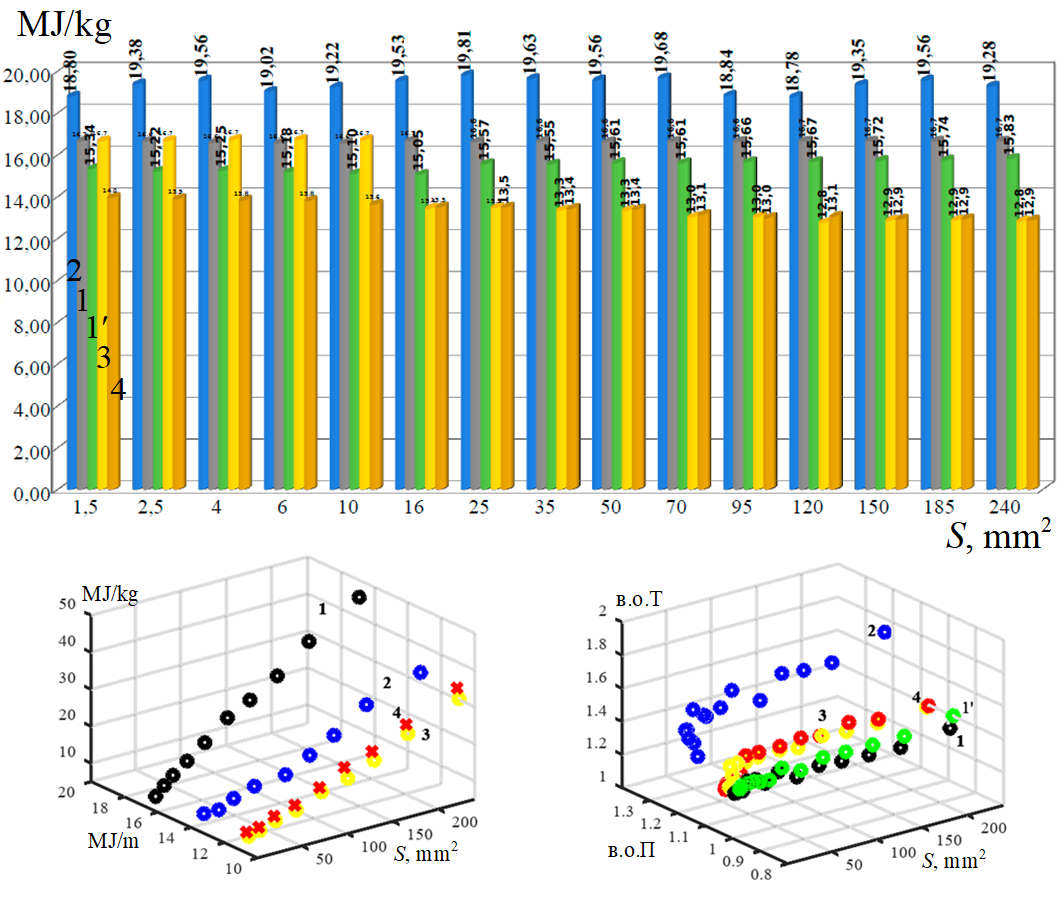

Introduction. One of the main driving factors of the demand for cable and conductor products is the modern trend of urbanization, which leads to an increase in cities with significantly increased requirements for electrical networks of transportation and distribution of electrical energy. This requires the development of appropriate infrastructure with significant demand for electricity in the commercial, industrial and residential sectors. The construction industry uses a wide range of cables with an appropriate set of electrical and mechanical properties, resistance to the influence of external climatic factors, and, first of all, must meet fire safety requirements. Increasing construction activity is stimulating the market for fire-resistant cables in the construction industry. According to the Construction Products Regulation, power, telecommunication cables, data cables, control and management, fiber optic refer to construction products in the EU member states. These cables are intended for the supply of electrical energy and communication, which are permanently installed in buildings and other engineering structures. Power, telecommunications, data and control cables are considered construction products, and are the only electrical products classified as construction. Over the next 15 years, Eastern Europe is expected to see increased growth in the construction industry, as the end of the war in Ukraine requires nearly $1 trillion in reconstruction. A strategic task in the reconstruction of the country is the use of cable and conductor products with increased operational properties, including in the construction industry. Significant efforts and investments in innovation and certification of cable and conductor products require manufacturers to create construction products of the «Power, control and communication cables» category with a high level of fire safety in accordance with the Euroclassification of cables in terms of reaction to fire depending on the level of safety. Purpose. Analysis of fire safety requirements for cables as a category of construction products and determination of thermal resistance of power cables based on experimental thermal studies of modern electrical insulating compositions. Methodology. The thermal stability of power cables with a voltage of 0,66/1 kV was determined, depending on the design, based on the conducted experimental studies of the thermal stability of electrical insulation materials, between the core filling and the polymer sheath, removed from the cable samples. On the basis of the conducted correlation analysis between thermal resistance and fire load, which are important parameters for confirming the quality and safety of the entire cable, it has been proven that the efficiency of halogen-free compositions to meet fire safety requirements increases with the increase in the cross-section and number of cores in the cable. Practical value. Determining the heat load and fire resistance of cables of various designs and areas of application based on the obtained experimental data on the heat of combustion of polymer cable materials is necessary and justified at the stage of mastering and determining the prospects for the production of cables with modern halogen-free electrical insulation compositions in accordance with fire safety requirements.

References

Wires And Cables Market Size, Share & Trend Analysis Report By Voltage (Low, Medium, High, Extra-High), By Installation (Overhead, Underground), By End-Use, And Regional Forecasts, 2023 – 2030. 2022, 120 p.

Wire and Cable Market – By Product (Coaxial Cables/Electronic Wires, Fiber Optics Cables, Power Cables, Signal & Control Cable, Telecom & Data Cables), By Voltage (Low, Medium, High), By Application & Forecast, 2023-2032. 2023, 320 p.

Global Wire and Cable Materials Market (2022 to 2030): Industry Analysis, Size, Share, Growth, Trends, and Forecasts.

Maes J., Nuzman C.J. The Past, Present, and Future of Copper Access. Bell Labs Technical Journal, 2015, vol. 20, pp. 1-10. doi: https://doi.org/10.15325/BLTJ.2015.2397851.

Harting. Single pair Ethernet. The infrastructure for IioT. HARTING. 2020, 20 p.

Construction Future. Oxford Economics. Research Briefing, June, 21, 2023.

Global Building Materials Industry 2023 2027. Report. 2023, 179 p.

Europe Construction Market Report and Forecast 2023-2028. Report. 2023, 80 p.

Recommendation for Use adopted by the Cableways Sectoral Group of Notified Bodies, and agreed by the Cableways Expert Group. 2021. 5 р.

Günter Beyer The Global Cable Industry: Materials, Markets, Products. 2021, 416 p.

Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products and repealing Council Directive 89/106/EEC (Text with EEA relevance) (Consolidated text).

Commission Delegated Regulation (EU) 2016/364 of 1 July 2015 on the classification of the reaction to fire performance of construction products pursuant to Regulation (EU) No 305/2011 of the European Parliament and of the Council.

Pedersen L.L. Cables for the EU must be CE marked. 2017.

DSTU EN 60228:2015 Conductors of insulated cables. General technical requirements (EN 60228:2004, AC:2005). (Ukr).

IEC 60811-501:2012+AMD1:2018. Electric and optical fibre cables. Test methods for non-metallic materials. Part 501: Mechanical tests. Tests for determining the mechanical properties of insulating and sheathing compounds. Edition 1.1. IEC TC 20, 2018. 67 p.

Mirchuk I.A. Halogen-free compositions for cable and wire products. Advantages, disadvantages and application features. The Scientific Heritage, 2018, vol. 1, no. 30, pp. 32-41. (Rus).

Bezprozvannych G.V., Mirchuk I.A. Synthesis of technological modes of cooling and radiation testing of electrical insulation of cables. Monograph. Kharkiv, Madrid Publ., 2021. 179 p. (Ukr).

Xu J., Ou H., Shan X., Liu B., Jiang J., Xu G. Investigation of novel intumescent flame retardant low‐density polyethylene based on SiO 2 @MAPP and double pentaerythritol. Journal of Applied Polymer Science, 2020, vol. 137, no. 41, art. no. 49242 doi: https://doi.org/10.1002/app.49242.

Li Y., Qi L., Liu Y., Qiao J., Wang M., Liu X., Li S. Recent Advances in Halogen-Free Flame Retardants for Polyolefin Cable Sheath Materials. Polymers, 2022, vol. 14, no. 14, art. no. 2876. doi: https://doi.org/10.3390/polym14142876.

IEC 60811-100:2012 Electric and optical fibre cables – Test methods for non-metallic materials – Part 100: General. 21 p.

EN 50363-0:2011 Insulating, sheathing and covering materials for low-voltage energy cables – Part 0: General introduction. 2023, 10 p.

Restriction of the use of certain hazardous substances (RoHS). Directive 2011/65/EU.

Zolotaryov V.M., Chulieieva O.V., Chulieiev V.L., Kuleshova T.A., Suslin M.S. Influence of doping additive on thermophysical and rheological properties of halogen-free polymer composition for cable insulation and sheaths. Electrical Engineering & Electromechanics, 2022, no. 2, pp. 35-40. doi: https://doi.org/10.20998/2074-272X.2022.2.06.

Bezprozvannych G.V., Zolotaryov V.M., Antonets Y.A. Effect of the thickness of insulation of protected wires of high-voltage overhead transmission lines to their current carrying capacity. Electrical Engineering & Electromechanics, 2018, no. 2, pp. 41-46. doi: https://doi.org/10.20998/2074-272X.2018.2.07.

Porowski R., Kowalik R., Ramiączek P., Bąk-Patyna P., Stępień P., Zielecka M., Popielarczyk T., Ludynia A., Chyb A., Gawdzik J. Application Assessment of Electrical Cables during Smoldering and Flaming Combustion. Applied Sciences, 2023, vol. 13, no. 6, art. no. 3766. doi: https://doi.org/10.3390/app13063766.

Fangrat J., Kaczorek-Chrobak K., Papis B.K. Fire Behavior of Electrical Installations in Buildings. Energies, 2020, vol. 13, no. 23, art. no. 6433. doi: https://doi.org/10.3390/en13236433.

Wang K., Kong G., Shao M., Yu Q., Yang R. Study on Flame Retardancy of Enamelled Wires Using a Cone Calorimeter. Journal of Physics: Conference Series, 2023, vol. 2460, no. 1, art. no. 012014. doi: https://doi.org/10.1088/1742-6596/2460/1/012014.

DSTU EN 13501-6:2019 Fire classification of building products and building structures. Part 6. Classification according to the results of the test for reaction to fire of power, control and communication cables (EN 13501-6:2018, IDT). (Ukr).

DSTU EN 50399:2016 General methods of fire tests. Determination of heat release and smoke generation indicators of cables during the flame propagation test. Test equipment. Test procedures and evaluation of results (EN 50399:2011, IDT). 2016, 11 p. (Ukr).

DSTU EN ISO 1716:2019 Testing of products for reaction to fire. Determination of the heat of combustion (calorific value) (EN ISO 1716:2018, IDT; ISO 1716:2018, IDT). (Ukr).

DSTU EN 60332-1-2:2017 (EN 60332-1-2:2004; A1:2015; A11:2016, IDT; IEC 60332-1-2:2004; A1:2015, IDT) Fire tests of electrical and fiber optic cables. Part 1-2. Test for vertical spread of flame of a single insulated wire or cable. The method of testing with a flame of a premixed type with a capacity of 1 kW. National standard of Ukraine. Kyiv, SE UkrNDNC Publ., 2017. 12 p. (Ukr).

DSTU 4809:2007. Insulated wires and cables. Fire safety requirements and test methods. Kyiv, Derzhspozhivstandard of Ukraine, 2007. 14 p. (Ukr).

DSTU IES 60502-1:2009 Power cables with extruded insulation and fittings for them for a nominal voltage from 1 kV (Um = 1.2 kV) to 30 kV (Um = 36 kV). Part 1. Cables for a nominal voltage of 1 kV (Um = 1.2 kV) and 3 kV (Um = 3.6 kV) (IEC 60502-1:2004, IDT). National standard of Ukraine. Kyiv, SE UkrNDNC Publ., 2011. 44 p. (Ukr).

Bezprozvannych G.V., Grynyshyna M.V., Kyessayev A.G., Grechko O.M. Providing technical parameters of resistive cables of the heating floor system with preservation of thermal resistance of insulation. Electrical Engineering & Electromechanics, 2020, no. 3, pp. 43-47. doi: https://doi.org/10.20998/2074-272X.2020.3.07.

Bezprozvannych G.V., Mirchuk I.A. Correlation between electrical and mechanical characteristics of cables with radiation-modified insulation on the basis of a halogen-free polymer composition. Electrical Engineering & Electromechanics, 2018, no. 4, pp. 54-57. doi: https://doi.org/10.20998/2074-272X.2018.4.09.

Di Nenno P.J. The SFPE Handbook of Fire Protection Engineering, 4th ed. National Fire Protection Association, Quincy, MA, USA, 2008. 1604 p.

Hirschler M.M. Flame retardants and heat release: review of traditional studies on products and on groups of polymers. Fire and Materials, 2015, vol. 39, no. 3, pp. 207-231. doi: https://doi.org/10.1002/fam.2243.

Li C., Chen J., Zhang W., Hu L., Cao J., Liu J., Zhu Z., Wu S. Influence of Arc Size on the Ignition and Flame Propagation of Cable Fire. Energies, 2021, vol. 14, no. 18, art. no. 5675. doi: https://doi.org/10.3390/en14185675.

Meinier R., Fellah M., Sonnier R., Zavaleta P., Suard S., Ferry L. Ignition and Charring of PVC-Based Electric Cables. Fire Technology, 2022, vol. 58, no. 2, pp. 689-707. doi: https://doi.org/10.1007/s10694-021-01168-0.

Bezprozvannych G.V., Mirchuk I.A. The evaluation of possibility of normal operation of cables based on twisted pairs with pvc jacket under the conditions of high humidity and temperature. Electrical Engineering & Electromechanics, 2017, no. 5, pp. 51-54. doi: https://doi.org/10.20998/2074-272X.2017.5.08.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 G. V. Bezprozvannych, M. V. Grynyshyna, Y. S. Moskvitin

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Authors who publish with this journal agree to the following terms:

1. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.