Internal capacitive compensation of the reactive power of the screw electromechanical converter

DOI:

https://doi.org/10.20998/2074-272X.2024.3.02Keywords:

Maxwell’s equation, multifunctional electromechanical converter, stator winding, finite element method, capacitor capacityAbstract

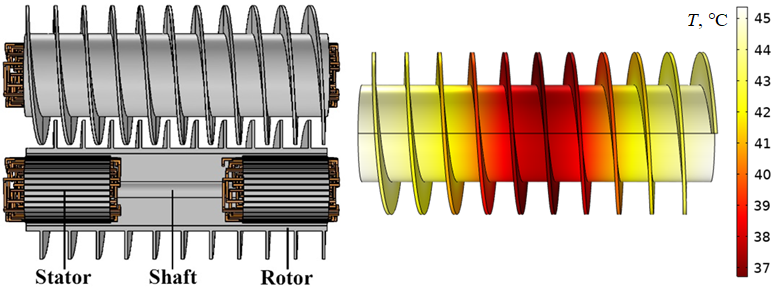

Introduction. A special category among induction machines with a massive rotor is occupied by the class of multifunctional electromechanical energy converters, which are integrated with the links of technological processes Problem. The exchange of reactive energy between the source and the electromechanical converter during periods of operation with a low load leads to a significant decrease in its efficiency and power factor. With the use of non-linear loads and taking into account possible resonance, it has become more difficult to improve the power factor by installing capacitor banks. Goal. Increasing the energy indicators of the electromechanical converter by spatial displacement of the main and additional stator windings and internal capacitive compensation. Methodology. Comparative analysis of connection schemes and spatial arrangement of stator windings when using internal capacitive compensation. Modeling and experimental studies of electromagnetic and electromechanical characteristics of a screw electromechanical converter. Results. The distribution of electromagnetic quantities was established and the choice of the angle of spatial displacement of the main and additional windings of the stator phases of the modified converter, which ensure an increase in the value of the electromagnetic torque and power factor, was justified. The results of experimental studies of the screw electromechanical converter are presented. Originality. For the first time, a method of internal capacitive compensation of reactive power is proposed for multifunctional electromechanical converters of technological purpose. Practical value. The use of the proposed method of spatial displacement of the main and additional stator windings and internal capacitive compensation will ensure an increase in the energy performance of the screw electromechanical converter. References 23, tables 3, figures 15.

References

Zhitao Han, Li Ding, Gang Wang. Experimental Investigation of Induction Motor Power Factor and Efficiency Impacted by Pulse Width Modulation Power and Voltage Controls of Variable-Frequency Drives. ASHRAE Transactions, 2021, vol. 127, pp. 817-828.

Bortoni E.C., Bernardes J.V., da Silva P.V.V., Faria V.A.D., Vieira P.A.V. Evaluation of manufacturers strategies to obtain high-efficient induction motors. Sustainable Energy Technologies and Assessments, 2019, vol. 31, pp. 221-227. doi: https://doi.org/10.1016/j.seta.2018.12.022.

Mbinkar E.N., Asoh D.A., Kujabi S. Microcontroller Control of Reactive Power Compensation for Growing Industrial Loads. Energy and Power Engineering, 2022, vol. 14, no. 9, pp. 460-476. doi: https://doi.org/10.4236/epe.2022.149024.

Habyarimana M., Dorrell D.G., Musumpuka R. Reduction of Starting Current in Large Induction Motors. Energies, 2022, vol. 15, no. 10, art. no. 3848. doi: https://doi.org/10.3390/en15103848.

Antar R.K., Suliman M.Y., Saleh A.A. Harmonics resonance elimination technique using active static compensation circuit. Bulletin of Electrical Engineering and Informatics, 2021, vol. 10, no. 5, pp. 2405-2413. doi: https://doi.org/10.11591/eei.v10i5.3148.

Ferreira F.J.T.E., de Almeida A.T. Novel Multiflux Level, Three-Phase, Squirrel-Cage Induction Motor for Efficiency and Power Factor Maximization. IEEE Transactions on Energy Conversion, 2008, vol. 23, no. 1, pp. 101-109. doi: https://doi.org/10.1109/TEC.2007.914355.

Guo J., Ma X., Ahmadpour A. Electrical–mechanical evaluation of the multi–cascaded induction motors under different conditions. Energy, 2021, vol. 229, art. no. 120664. doi: https://doi.org/10.1016/j.energy.2021.120664.

Jagiela M., Garbiec T. Determination of best rotor length in solid-rotor induction motor with axial slitting. Archives of Electrical Engineering, 2012, vol. 61, no. 2, pp. 267-276. doi: https://doi.org/10.2478/v10171-012-0022-2.

Zablodskiy M., Gritsyuk V., Rudnev Y., Brozhko R. Three-dimensional electromagnetic field model of an auger electromechanical converter with an external solid rotor. Mining of Mineral Deposits, 2019, vol. 13, no. 4, pp. 99-106. doi: https://doi.org/10.33271/mining13.04.099.

Milykh V.I. Numerical-field analysis of active and reactive winding parameters and mechanical characteristics of a squirrel-cage induction motor. Electrical Engineering & Electromechanics, 2023, no. 4, pp. 3-13. doi: https://doi.org/10.20998/2074-272X.2023.4.01.

Trisha, Gupta G.S., Shiva Kumar S. Review of the Parameter Estimation and Transient Analysis of Three-Phase Induction Motor. Lecture Notes in Electrical Engineering, 2021, vol. 693, pp. 223-232. doi: https://doi.org/10.1007/978-981-15-7675-1_21.

Nasir B.A. An Accurate Iron Core Loss Model in Equivalent Circuit of Induction Machines. Journal of Energy, 2020, vol. 2020, pp. 1-10. doi: https://doi.org/10.1155/2020/7613737.

Ekpo E.G., Umoh G.D., Udokah Y.O.N. Effect of Phase-Shift in Six-Phase Induction Machine. Journal of Emerging Trends in Engineering and Applied Sciences, 2022, vol. 13, no. 6, pp. 215-226.

Saneie H., Nasiri-Gheidari Z. Performance Analysis of Outer-Rotor Single-Phase Induction Motor Based on Magnetic Equivalent Circuit. IEEE Transactions on Industrial Electronics, 2021, vol. 68, no. 2, pp. 1046-1054. doi: https://doi.org/10.1109/TIE.2020.2969125.

Sharma U., Singh B. Robust design methodology for single phase induction motor ceiling fan. IET Electric Power Applications, 2020, vol. 14, no. 10, pp. 1846-1855. doi: https://doi.org/10.1049/iet-epa.2020.0017.

Rezazadeh G., Tahami F., Capolino G.-A., Nasiri-Gheidari Z., Henao H., Sahebazamani M. Improved Design of an Outer Rotor Six-Phase Induction Motor With Variable Turn Pseudo-Concentrated Windings. IEEE Transactions on Energy Conversion, 2022, vol. 37, no. 2, pp. 1020-1029. doi: https://doi.org/10.1109/TEC.2021.3126538.

Tornello L.D., Foti S., Cacciato M., Testa A., Scelba G., De Caro S., Scarcella G., Rizzo S.A. Performance Improvement of Grid-Connected Induction Motors through an Auxiliary Winding Set. Energies, 2021, vol. 14, no. 8, art. no. 2178. doi: https://doi.org/10.3390/en14082178.

Di C., Petrov I., Pyrhonen J.J. Design of a High-Speed Solid-Rotor Induction Machine With an Asymmetric Winding and Suppression of the Current Unbalance by Special Coil Arrangements. IEEE Access, 2019, vol. 7, pp. 83175-83186. doi: https://doi.org/10.1109/ACCESS.2019.2925131.

Zablodsky N., Chuenko R., Gritsyuk V., Kovalchuk S., Romanenko O. The Numerical Analysis of Electromechanical Characteristics of Twin-Screw Electromechanical Hydrolyzer. 2021 11th International Conference on Advanced Computer Information Technologies (ACIT), 2021, pp. 130-135. doi: https://doi.org/10.1109/ACIT52158.2021.9548392.

Kaplun V., Makarevych S., Chuenko R. Modelling of Asynchronous Motor with Split Stator Windings on the Principle of a Rotary Autotransformer. Przeglad Elektrotechniczny, 2022, vol. 98, no. 3, pp. 39-43. doi: https://doi.org/10.15199/48.2022.03.10.

AC/DC Module User’s Guide. COMSOL Inc., Burlington, MA, USA, 2018.

Rezazadeh G., Tahami F., Capolino G.-A., Vaschetto S., Nasiri-Gheidari Z., Henao H. Improvement of Concentrated Winding Layouts for Six-Phase Squirrel Cage Induction Motors. IEEE Transactions on Energy Conversion, 2020, vol. 35, no. 4, pp. 1727-1735. doi: https://doi.org/10.1109/TEC.2020.2995433.

Heat Transfer Module User’s Guide. COMSOL Inc., Burlington, MA, USA, 2018.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 M. M. Zablodskiy, R. M. Chuenko, S. I. Kovalchuk, H. V. Kruhliak, O. I. Kovalchuk

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Authors who publish with this journal agree to the following terms:

1. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.