Fuzzy current analysis-based fault diagnostic of induction motor using hardware co-simulation with field programmable gate array

DOI:

https://doi.org/10.20998/2074-272X.2023.6.01Keywords:

asynchronous machine, fuzzy current analysis, field programmable gate array, hardware co-simulationAbstract

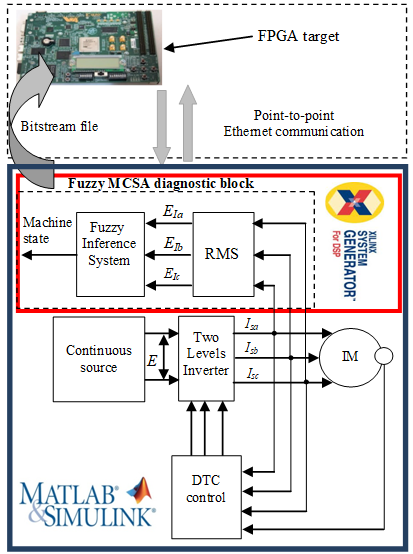

Introduction. Presently, signal analysis of stator current of induction motor has become a popular technique to assess the health state of asynchronous motor in order to avoid failures. The classical implementations of failure detection algorithms for rotating machines, based on microprogrammed sequential systems such as microprocessors and digital signal processing have shown their limitations in terms of speed and real time constraints, which requires the use of new technologies providing more efficient diagnostics such as application specific integrated circuit or field programmable gate array (FPGA). The purpose of this work is to study the contribution of the implementation of fuzzy logic on FPGA programmable logic circuits in the diagnosis of asynchronous machine failures for a phase unbalance and a missing phase faults cases. Methodology. In this work, we propose hardware architecture on FPGA of a failure detection algorithm for asynchronous machine based on fuzzy logic and motor current signal analysis by taking the RMS signal of stator current as a fault indicator signal. Results. The validation of the proposed architecture was carried out by a co-simulation hardware process between the ML402 boards equipped with a Virtex-4 FPGA circuit of the Xilinx type and Xilinx system generator under MATLAB/Simulink. Originality. The present work combined the performance of fuzzy logic techniques, the simplicity of stator current signal analysis algorithms and the execution power of ML402 FPGA board, for the fault diagnosis of induction machine achieving the best ratios speed/performance and simplicity/performance. Practical value. The emergence of this method has improved the performance of fault detection for asynchronous machine, especially in terms of hardware resource consumption, real-time online detection and speed of detection.

References

Sakhara S., Brahimi M., Nacib L., Layadi T.M. Application of a wavelet neural network approach to detect stator winding short circuits in asynchronous machines. Electrical Engineering & Electromechanics, 2023, no. 3, pp. 21-27. doi: https://doi.org/10.20998/2074-272X.2023.3.03.

Moussaoui L., Aouaouda S., Rouaibia R. Fault tolerant control of a permanent magnet synchronous machine using multiple constraints Takagi-Sugeno approach. Electrical Engineering & Electromechanics, 2022, no. 6, pp. 22-27. doi: https://doi.org/10.20998/2074-272X.2022.6.04.

Da Costa C., Santin C.O. FPGA design approach of digital control of three-phase induction motor. 2017 Brazilian Power Electronics Conference (COBEP), 2017, pp. 1-6. doi: https://doi.org/10.1109/COBEP.2017.8257221.

Lipo T.A., Consoli A. Modeling and Simulation of Induction Motors with Saturable Leakage Reactances. IEEE Transactions on Industry Applications, 1984, vol. IA-20, no. 1, pp. 180-189. doi: https://doi.org/10.1109/TIA.1984.4504392.

Cornell E.P., Lipo T.A. Modeling and Design of Controlled Current Induction Motor Drive Systems. IEEE Transactions on Industry Applications, 1977, vol. IA-13, no. 4, pp. 321-330. doi: https://doi.org/10.1109/TIA.1977.4503414.

Toliyat H.A., Lipo T.A. Transient analysis of cage induction machines under stator, rotor bar and end ring faults. IEEE Transactions on Energy Conversion, 1995, vol. 10, no. 2, pp. 241-247. doi: https://doi.org/10.1109/60.391888.

Devanneaux V., Dagues B., Faucher J., Barakat G. An accurate model of squirrel cage induction machines under stator faults. Mathematics and Computers in Simulation, 2003, vol. 63, no. 3–5, pp. 377-391. doi: https://doi.org/10.1016/S0378-4754(03)00083-1.

Filippetti F., Franceschini G., Tassoni C., Vas P. Recent developments of induction motor drives fault diagnosis using AI techniques. IEEE Transactions on Industrial Electronics, 2000, vol. 47, no. 5, pp. 994-1004. doi: https://doi.org/10.1109/41.873207.

Filippetti F., Franceschini G., Tassoni C. Neural networks aided on-line diagnostics of induction motor rotor faults. Conference Record of the 1993 IEEE Industry Applications Conference Twenty-Eighth IAS Annual Meeting, 1993, pp. 316-323. doi: https://doi.org/10.1109/IAS.1993.298942.

Abu Ibaid O.Z.I., Belhamdi S., Abid M., Chakroune S., Mouassa S., Al-Sagar Z.S. Wavelet packet analysis for rotor bar breakage in an inverter induction motor. Electrical Engineering & Electromechanics, 2023, no. 3, pp. 3-11. doi: https://doi.org/10.20998/2074-272X.2023.3.01.

Bellini A., Filippetti F., Franceschini G., Tassoni C. Closed-loop control impact on the diagnosis of induction motors faults. IEEE Transactions on Industry Applications, 2000, vol. 36, no. 5, pp. 1318-1329. doi: https://doi.org/10.1109/28.871280.

Schoen R.R., Lin B.K., Habetler T.G., Schlag J.H., Farag S. An unsupervised, on-line system for induction motor fault detection using stator current monitoring. IEEE Transactions on Industry Applications, 1995, vol. 31, no. 6, pp. 1280-1286. doi: https://doi.org/10.1109/28.475698.

Said M.S.N., Benbouzid M.E.H., Benchaib A. Detection of broken bars in induction motors using an extended Kalman filter for rotor resistance sensorless estimation. IEEE Transactions on Energy Conversion, 2000, vol. 15, no. 1, pp. 66-70. doi: https://doi.org/10.1109/60.849118.

Nejjari H., Benbouzid M.E.H. Monitoring and diagnosis of induction motors electrical faults using a current Park’s vector pattern learning approach. IEEE Transactions on Industry Applications, 2000, vol. 36, no. 3, pp. 730-735. doi: https://doi.org/10.1109/28.845047.

Kral C., Pirker F., Pascoli G. Detection of rotor faults in squirrel-cage induction machines at standstill for batch tests by means of the Vienna monitoring method. IEEE Transactions on Industry Applications, 2002, vol. 38, no. 3, pp. 618-624. doi: https://doi.org/10.1109/TIA.2002.1003409.

Hsu J.S. Monitoring of defects in induction motors through air-gap torque observation. IEEE Transactions on Industry Applications, 1995, vol. 31, no. 5, pp. 1016-1021. doi: https://doi.org/10.1109/28.464514.

Lehtoranta J., Koivo H.N. Fault Diagnosis of Induction Motors with Dynamical Neural Networks. 2005 IEEE International Conference on Systems, Man and Cybernetics, 2005, vol. 3, pp. 2979-2984. doi: https://doi.org/10.1109/ICSMC.2005.1571603.

Karim E., Memon T.D., Hussain I. FPGA based on-line fault diagnostic of induction motors using electrical signature analysis. International Journal of Information Technology, 2019, vol. 11, no. 1, pp. 165-169. doi: https://doi.org/10.1007/s41870-018-0238-5.

Rajeswaran N., Thangaraj R., Mihet-Popa L., Krishna Vajjala K.V., Özer Ö. FPGA Implementation of AI-Based Inverter IGBT Open Circuit Fault Diagnosis of Induction Motor Drives. Micromachines, 2022, vol. 13, no. 5, art. no. 663. doi: https://doi.org/10.3390/mi13050663.

Chouidira I., Khodja D., Chakroune S. Induction Machine Faults Detection and Localization by Neural Networks Methods. Revue d’Intelligence Artificielle, 2019, vol. 33, no. 6, pp. 427-434. doi: https://doi.org/10.18280/ria.330604.

Romero-Troncoso R.J., Saucedo-Gallaga R., Cabal-Yepez E., Garcia-Perez A., Osornio-Rios R.A., Alvarez-Salas R., Miranda-Vidales H., Huber N. FPGA-Based Online Detection of Multiple Combined Faults in Induction Motors Through Information Entropy and Fuzzy Inference. IEEE Transactions on Industrial Electronics, 2011, vol. 58, no. 11, pp. 5263-5270. doi: https://doi.org/10.1109/TIE.2011.2123858.

Aib A., Khodja D.E., Chakroune, S. Field programmable gate array hardware in the loop validation of fuzzy direct torque control for induction machine drive. Electrical Engineering & Electromechanics, 2023, no. 3, 28-35. doi: https://doi.org/10.20998/2074-272X.2023.3.04.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 A. Aib, D. E. Khodja, S. Chakroune, H. Rahali

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Authors who publish with this journal agree to the following terms:

1. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.