Axial flux machine with non-slotted torus-ns rotor type. Design and investigate for electric traction

DOI:

https://doi.org/10.20998/2074-272X.2023.6.02Keywords:

axial flux permanent magnet machine, electric vehicle, finite element method, TORUS-NSAbstract

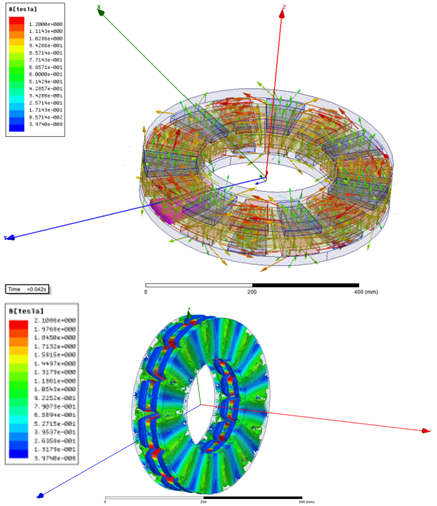

Introduction. The drive electric motor is one of the key components in the traction chain of an electric vehicle. Traditional radial flux motors used in electric vehicles, which use permanent magnets or induction motors in an electric field, are experiencing significant development aimed at optimizing their weight and cost. However, it can only go so far, so switching to a completely different type of machine, such as an axial flow, might be a good alternative. The novelty to this item is an axial flux permanent magnet motorization with non-slotted TORUS-NS rotor (single interior stator with two external rotors North-South) type housed in the wheel of the vehicle; this allows power to pass directly from the motor to the wheel, increasing the efficiency of the motor. System complexity is also less, as the transmission, differentials and driveshaft are eliminated. Purpose is to equip the electric car and choose the motor adapted to the application and the available space. The smaller size and weight allows for a lighter vehicle and more batteries, thus increasing range. The focus on customization is because vehicle performance is so dependent on the quality of the vehicle architecture , battery pack and axial flux motor design. The results obtained are in good agreement of accuracy, in particular the flux density at the air gap. The investigation is carried out by the finite element method. Machine model was run on Maxwell 16.0 business code.

References

Lasocki J., Krawczyk P., Kopczyński A., Roszczyk P., Hajduga A. Analysis of the strategies for managing extended-range electric vehicle powertrain in the urban driving cycle. Electrical Engineering & Electromechanics, 2022, no. 1, pp. 70-76. doi: https://doi.org/10.20998/2074-272X.2022.1.10.

Caricchi F., Crescimbini F., Mezzetti F., Santini E. Multi-stage axial-flux PM machine for wheel direct drive. IAS ’95. Conference Record of the 1995 IEEE Industry Applications Conference Thirtieth IAS Annual Meeting, 1995, vol. 1, pp. 679-684. doi: https://doi.org/10.1109/IAS.1995.530365.

Vun S.T., McCulloch M.D. Optimal Design Method for Large-Scale YASA Machines. IEEE Transactions on Energy Conversion, 2015, vol. 30, no. 3, pp. 900-907. doi: https://doi.org/10.1109/TEC.2015.2397342.

Fan J., Lee Y. Sensorless control of switched reluctance motor based on a simple flux linkage model. Electrical Engineering & Electromechanics, 2023, no. 3, pp. 36-39. doi: https://doi.org/10.20998/2074-272X.2023.3.05.

Si J., Zhang T., Hu Y., Gan C., Li Y. An Axial-Flux Dual-Rotor Slotless Permanent Magnet Motor With Novel Equidirectional Toroidal Winding. IEEE Transactions on Energy Conversion, 2022, vol. 37, no. 3, pp. 1752-1763. doi: https://doi.org/10.1109/TEC.2021.3138465.

Patel A.N. Slot opening displacement technique for cogging torque reduction of axial flux brushless DC motor for electric two-wheeler application. Electrical Engineering & Electromechanics, 2023, no. 2, pp. 7-13. doi: https://doi.org/10.20998/2074-272X.2023.2.02.

Jacekf G., Rong W., Maarten K. Axial Flux Permanent Magnet Brushless Machines. 2nd Ed. Springer, 2008.

Caricchi F., Crescimbini F., Honorati O. Low-cost compact permanent magnet machine for adjustable-speed pump application. IEEE Transactions on Industry Applications, 1998, vol. 34, no. 1, pp. 109-116. doi: https://doi.org/10.1109/28.658730.

Gonzalez-Lopez D.A., Tapia J.A., Wallace R., Valenzuela A. Design and Test of an Axial Flux Permanent-Magnet Machine With Field Control Capability. IEEE Transactions on Magnetics, 2008, vol. 44, no. 9, pp. 2168-2173. doi: https://doi.org/10.1109/TMAG.2008.2000543.

Abu Ibaid O.Z.I., Belhamdi S., Abid M., Chakroune S., Mouassa S., Al-Sagar Z.S. Wavelet packet analysis for rotor bar breakage in an inverter induction motor. Electrical Engineering & Electromechanics, 2023, no. 3, pp. 3-11. doi: https://doi.org/10.20998/2074-272X.2023.3.01.

Profumo F., Zheng Zhang, Tenconi A. Axial flux machines drives: a new viable solution for electric cars. IEEE Transactions on Industrial Electronics, 1997, vol. 44, no. 1, pp. 39-45. doi: https://doi.org/10.1109/41.557497.

Liu C.-T., Lee S.-C. Magnetic field modeling and optimal operational control of a single-side axial-flux permanent magnet motor with center poles. Journal of Magnetism and Magnetic Materials, 2006, vol. 304, no. 1, pp. e454-e456. doi: https://doi.org/10.1016/j.jmmm.2006.02.065.

Gholamian S.A., Ardebil M., Abbaszadeh K., Mahmodi Charati S. Optimum Design of 1 kW Axial Flux Permanent Magnet Slotted TORUS Motor. European Journal of Scientific Research, 2008, vol. 21, no. 3, pp. 488-499.

Dlala E. Comparison of Models for Estimating Magnetic Core Losses in Electrical Machines Using the Finite-Element Method. IEEE Transactions on Magnetics, 2009, vol. 45, no. 2, pp. 716-725. doi: https://doi.org/10.1109/TMAG.2008.2009878.

Gholamian S.A., Ardebili M., Abbaszadeh K. Analytic and FEM evaluation of power density for various types of double-sided axial flux slotted PM motors. International Journal of Applied Engineering Research (IJAER), 2008, vol. 3, no. 7, pp. 927-939.

Aydin M., Huang S., Lipo T.A. Optimum design and 3D finite element analysis of nonslotted and slotted internal rotor type axial flux PM disc machines. 2001 Power Engineering Society Summer Meeting. Conference Proceedings (Cat. No.01CH37262), 2001, vol. 3, pp. 1409-1416. doi: https://doi.org/10.1109/PESS.2001.970283.

Huang Y., Zhu J., Guo Y., Hu Q. Development of a High-Speed Claw Pole Motor with Soft Magnetic Composite Core. 2007 IEEE International Electric Machines & Drives Conference, 2007, pp. 1564-1568. doi: https://doi.org/10.1109/IEMDC.2007.383661.

Surong Huang, Jian Luo, Leonardi F., Lipo T.A. A comparison of power density for axial flux machines based on general purpose sizing equations. IEEE Transactions on Energy Conversion, 1999, vol. 14, no. 2, pp. 185-192. doi: https://doi.org/10.1109/60.766982.

Jiang C., Qiao M., Zhu P., Zheng Q. Design and Verification of High Speed Permanent Magnet Synchronous Motor for Electric Car. 2018 2nd IEEE Advanced Information Management,Communicates,Electronic and Automation Control Conference (IMCEC), 2018, pp. 2371-2375. doi: https://doi.org/10.1109/IMCEC.2018.8469398.

Aydin M., Huang S., Lipo T.A. Axial flux permanent magnet disc machines: A review. Conf. Record of SPEEDAM, 2004, vol. 8, pp. 61-71.

Yatchev I., Balabozov I., Hinov K., Hadzhiev I., Gueorgiev V. Influence of the shape of the input pulses on the characteristics of hybrid electromagnetic system with magnetic flux modulation. Electrical Engineering & Electromechanics, 2021, no. 3, pp. 3-7. doi: https://doi.org/10.20998/2074-272X.2021.3.01.

Belkacem L., Mustapha H., Katia K., Ahmed G. Design and Investigation of Axial Flux Permanent Magnet Synchronous Machine for electric vehicles. 2018 International Conference on Communications and Electrical Engineering (ICCEE), 2018, pp. 1-6. doi: https://doi.org/10.1109/CCEE.2018.8634529.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 B. Larbi, M. Hatti, K. Kouzi, A. Ghadbane

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Authors who publish with this journal agree to the following terms:

1. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.