Expansion of cylindrical tubular workpieces on high-voltage magnetic-pulse installation with controlled vacuum discharger

DOI:

https://doi.org/10.20998/2074-272X.2021.3.07Keywords:

high-voltage magnetic-pulse installations, capacitive energy storage, controlled vacuum discharger, current pulse «cut», probability of «cut», external coil, expansion of cylindrical tubular workpiece, part of complicated shapeAbstract

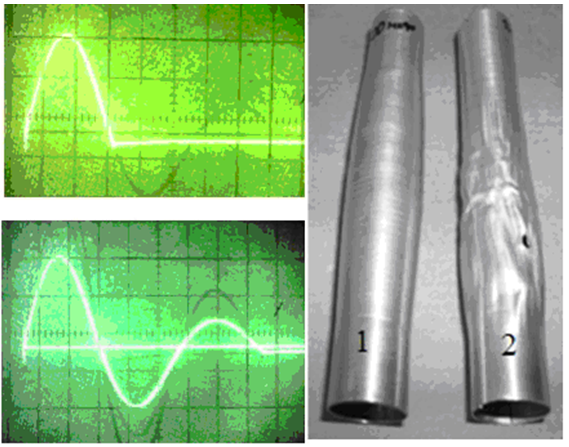

Purpose. An experimental verification of the existence of a range of values for the parameters of the capacitive energy storage of the magnetic-pulse installations with controlled vacuum discharger, in which, with a high probability, there is a «cut» of the discharge current pulses and the expansion of cylindrical thin-walled tubular workpieces using an external coil. Methodology. High voltage magnetic-pulse installation of NTU «KhPI» with controlled vacuum discharger, multiturn coil with inside dielectrical die and inside aluminum alloy workpiece are used. The capacitance and charge voltage of capacitive energy storage are changed. Discharge current pulses are measured by Rogowski coil and the oscillograph. Results. Parts of complicated shape are made by expansion of cylindrical tubular workpieces with help of external coil. Pressed metallic tubular part is removable from inner dielectric rod. Originality. The frequency of «cut» pulse is defined by negative magnetic field pressure amplitude. It is shown that we must coordinate this frequency and charge voltage with capacitive storage parameters by high probability of pulse «cut». Practical value. It is shown how to use installations with controlled vacuum dischargers in magnetic forming technology based on «cut» pulses.

References

Bely I.V., Fertik S.M., Khimenko L.T. Spravochnik po magnitno-impulsnoj obrabotke metallov [Handbook on magnetic-pulse processing of metals]. Kharkiv, Vishcha shkola Publ., 1977, 168 p. (Rus).

Psyk V., Risch D., Kinsey B.L., Tekkaya A.E., Kleiner M. Electromagnetic forming – A review. Journal of Materials Processing Technology, 2011, vol. 211, no. 5, pp. 787-829. doi: https://doi.org/10.1016/j.jmatprotec.2010.12.012.

Qiu L., Yu Y., Yang Y., Nie X., Xiao Y., Ning Y., Wang F., Cao C. Analysis of electromagnetic force and experiments in electromagnetic forming with local loading. International Journal of Applied Electromagnetics and Mechanics, 2018, vol. 57, no. 1, pp. 29-37. doi: https://doi.org/10.3233/jae-170038.

Zhang X., Li C., Wang X., Zhao Y., Li L. Improvement of deformation behavior of tube in electromagnetic forming with a triple-coil system. International Journal of Applied Electromagnetics and Mechanics, 2019, vol. 61, no. 2, pp. 263-272. doi: https://doi.org/10.3233/jae-180122.

Prokofiev A.B., Beliaeva I.A., Glushchenkov V.A., Karpukhin V.F., Chernikov D.G., Iusupov R.Iu. Magnitno-impul'snaia obrabotka materialov [Magnetic-pulse processing of materials]. Samara, SNTs Publ., 2019. 140 p, Available at: http://repo.ssau.ru/handle/Monografii/Magnitnoimpulsnaya-obrabotka-materialov-MIOM-Elektronnyi-resurs-monografiya-81514 (accessed 15 May 2020). (Rus).

Li X., Cao Q., Lai Z., Ouyang S., Liu N., Li M., Han X., Li L. Bulging behavior of metallic tubes during the electromagnetic forming process in the presence of a background magnetic field. Journal of Materials Processing Technology, 2020, vol. 276, p. 116411. doi: https://doi.org/10.1016/j.jmatprotec.2019.116411.

Xiong Q., Yang M., Tang H., Huang H., Song X., Qiu L., Yu K., Cao Q. Flaring Forming of Small Tube Based on Electromagnetic Attraction. IEEE Access, 2020, vol. 8, pp. 104753-104761. doi: https://doi.org/10.1109/access.2020.2999125.

Chernikov D.G., Glushchenkov V.A., Gusev D.V., Pfetzer I.A., Alyokhina V.K. Evaluation of the efficiency of the process of electromagnetic forming of small-diameter tubes. Izvestiya of Samara Scientific Center of the Russian Academy of Sciences, 2020, vol. 22, no. 4, pp. 21-28. (Rus). doi: https://doi.org/10.37313/1990-5378-2020-22-4-21-28.

Furth Harold P. Devices for metal-forming by magnetic tension. Patent USA no. 3,196,649, July, 27, 1965.

Shcheglov B.A., Esin A.A. Distribution of thin-walled tubular workpieces by the forces of attraction of a pulsed magnetic field. Forging and Stamping Production. Material Working by Pressure, 1971, no. 4, pp. 15-17. (Rus).

Yusupov R.Yu. Magnetic-pulse installations of a new generation for industrial and educational-scientific purposes. Proceedings of the International Scientific and Technical Conference MIOM-2007, 2007, pp. 251-259. (Rus).

Bondina N.N., Konovalov O. Ya., Legeza A.V., Makeev V.G., Mikhailov V.M., Shovkoplyas A.V. Magnetic-pulse expansion of a cylindrical conducting shell and creation of a given distribution fields using an external inductor. Technical electrodynamics. Thematic issue «Problems of modern electrical engineering», 2008, chapter 5, pp. 84-89. (Rus).

Ljutenko L.A., Mikhailov V.M. The probability of interruption current pulses in circuit of capacitor bank with vacuum discharger. Technical electrodynamics, 2012, no. 3, pp. 121-122. (Rus).

Ljutenko L.A., Mikhailov V.M. Influence of the shape of an external magnetic field pulse on electrodynamic forces deforming a cylindrical shell. Technical electrodynamics, 2007, no. 6, pp. 15-19. (Rus).

Bondina N.N., Kramchanin E.G., Ljutenko L.A., Mikhailov V.M. Electrodynamic forces acting on a cylindrical shell under oscillating discharge of a magnetic pulse forming machine. Electrical Engineering & Electromechanics, 2007, no. 5, pp. 66-70. (Rus).

Boltachev G.Sh., Volkov N.B., Paranin S.N., Spirin A.V. Dynamics of cylindrical conducting shells in a pulsed longitudinal magnetic field. Technical Physics, 2010, vol. 55, no. 6, pp. 753-761. doi: https://doi.org/10.1134/S1063784210060010.

Neyman L.R., Demirchyan K.S. Teoreticheskie osnovy elektrotechniki. V 2-h tomah. Tom 2 [Theoretical bases of the Electrical Engineering. In 2 vols. Vol. 2]. Leningrad, Energoizdat Publ., 1981. 416 p. (Rus).

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 L. A. Ljutenko, V. M. Mikhailov

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

Authors who publish with this journal agree to the following terms:

1. Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

2. Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

3. Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work.